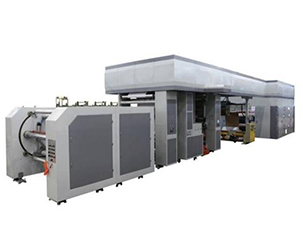

C.I. FLEXO PRESS 1600mm 5+1 COLORS

Name:

C.I. FLEXO PRESS 1600mm 5+1 COLORS

Sort:

Flexo Printer Series

Sort ID:

1600

Click:

1917 Times

C.I. FLEXO PRESS 1600mm 5+1 COLORS

SPECIFICATION

Printing material: paper 80-350gsm

Printing color: 5 colors+1 coating

Max. printing material width: 1620mm

Max. printing width: 1600mm

Printing repeat length: 800-1200mm

Max. machine speed: 220m/min

Printing speed: 200m/min,practice speed is affected by the following:

-printing layout perimeter

-printing ink and solvent

-printing layout and printing quality

Ink style: water based ink or solvent based ink

1200mm

1200mm

Splice style: no-stopping splicing

Driving style: gear driving method

Heating drying system: hot air heating system

Colophony plate and double side adhesive belt can be chosen by user:

(a) 1.7+0.38mm (b) 1.143+0.5mm

Adopt direct stick method

Electric standard: international standard IP40

Max. noise: not more than 70dBa

Suggestion operation temperature: 10-35 0C

Relative humidity: 30-80%(200C as reference temperature)

Elevation height : max. 1000mt

Machine color: white+grey

Main motor : Center drum vector frequency motor

Unwinding driving vector frequency motor

Rewinding driving vector frequency motor

Rewinding vector frequency motor

Total power:

Machine size(L×W×H): 22m×5.8m×5.5m

Compression air:

No lubrication, drying, wipe off humidity with filte

Air pressure:6Bar

Dew point:+20C

Cooling water:

Filter: less than 20u

Pressure: min.2Bar——max.3Bar

Entering water temperature(cooling roll, room temperature +200C):from 15 to 180C

Hardness(CaCO3):from 2.5 to 4 mg/l

PH:7 to 8.2

Vapour:

Pressure: min.6Bar——max.8Bar

Consumption: 450KG/H

Valve port dia. 40mm

- Double work station, hydraulic pressure with shaftless rack;

-Web clipping adopt cone-top, equip withΦ76, Φ150 mutual self-expansion chuck;

-Max. unwind dia. 1200mm;

-When web slip to other side, oerate hydraulic pressure button to transversally;

-All closed loop tension control.

-Adopt induced draft position equipment when paper receiving, oparation unit pneumatic flipping

device paper receiving and after that automatic cutting end paper;

Max. paper receiving speed 150m/min

- Max. paper receiving width 1620mm

-PLC automatic adjust floating position to ensure the tension stable during working;

- Zero velocity auto paper receiving: to ensure the tensin stable during high speed,

make fastness adhensive, and when paper starting through back up roller pneumatic

pressuriaing to make the tie-in fastness.

-Consist steel roller and rubber roller;

-Steel is driven roller, drived by vector frequency motor;

-Mainframe enter automatic running state, driving roller move with mainframe;

- Clutch pneumatic control rubber roller, both sides independent air cylinder pressure

can adjust identically.

- With paper double-faced dust elimination.

-Before entering printing unit, fix web guide device;

-Web guide controller: type KAMBEROLLER,one side electronic sensor,

manual or automatic adjustment, brand: Italy RE.

5.1 Printing frame

-High intension low stress alloy cast iron frame, twice treatment, high speed printing without quiver;

-Each printing unit crack adopt high intension low stress alloy cast iron;

-Cast iron can adjust level;

5.2 Central impression drum

-Import central impression drum from Italy;

-Double strcture of central impression, external diameter is 1528mm, flap precision is 0.01mm,

cylinder precision of drum surface can reach 0.012mm with high rigidity chromeplate;

-Imported high precision bearing supporting central drum and the whole structure is

imported to guarantee precision;

- Imported high precision big bevel wheel and the whole structure is imported with

central drum to guarantee precision;

-Driven by vector frequency motor, pneumatic urgent brake;

(YASKAWA closed loop vector frequency system 45Kw)

-Drum constant temperature control system and adjustment, the surface temperature is constant,

shaft temperature change is below ±2°

(customer provide cooling system).

5.3 Printing cylinder

-High precision machining cylinder, high precision bear supporting at both sides, turning precision

can reach 0.01mm,dynamic balance treatment precision can reach 10g;

-Cylinder surface high rigidity chromeplate;

-Each color printing cylinder is driven by high precision gear.

5.4 Anilox roller

-Laser engraved high precision ceramic anilox roller, thickness is 7.9mm, dynamic balance treatment

and precision is 15g;

- Ceramic anilox roller lines are from 250 to 900 lines, which can be made by customer’s demand;

-When printing wait, ceramic anilox roller can rotate to even ink at low speed independ.

-Each ceramic roller driven by gear wheel.

5.5 Closed blades and ink supplying system

-Aluminum alloy blades, closed ink, reduce solvent waste, keep ink clean;

-Front and back doctor, one is sealing and the other is scraping;

-Pneumatic pressing doctor, overall pressure is even, pressure can be adjusted by hand valve;

-Stainless steel ink supply stop, each color is equipped bump and back pipe road;

-Each color is equipped with stainless ink pan.

5.6 Printing unit moving device

-High intensity alloy cast iron, twice treatment;

-High precision silk bar motivate cylinder and anilox roller, 0.013grade high precision

infeeding adjustment structure, digital display operation, can operate at

printing unit control flat and central flat;

-Cylinde, r and anilox roller is driven by two in-phase motor, move precision is 0.01mm.

The adjustment pressure of cylinder, central drum and anilox roller can disply

at man machine conversation window;

-Impression can be adjusted at every side or at the same time, the date can be stored in

computer for use at any time, ;

-Cylinder base an anilox roller base slip on high precision rail freely;

-Pneumatic little move to drive cylinder and anilox roller leave and close pressure.

Anilox roller leave cylinder first when leave, and cylinder leave central,

drum when rotate 2/3 circular, then come back;

-Each printing unit with single control and can break away at any time;

-Cylinder and anilox roller adopt quick change installation structure,

can change quickly through electric motor sling equipment;

5.7 Register control

-Longitudinal register is adjusted by servo motor drive cylinder , register computer control register;

-Each printing cylinder operate in phase each other and keep the same step with central drum,

phase adjustment parameters can be done at printing unit operation flat and central control flat by automatic system;

-Transversal register adjustment is driven by servo motor, max. transversal range:±15mm。

-Longitudinal and transversal adjustment be done at central operation table and unit operation platform;

-Register check photoelectric monitor can be equipped with white light resource or blue light resource,

it is fit for transparence yellow etc. feeble reflection color printing.

–Register control precision is±0.1mm,register precision is constant when commonly accelerating or decelerating.

5.8 Printing unit control button station

-The control station can realize:start control, urgent control, button control, register adjustment,

printing cylinder and anilox roller pressure adjustment.

5.9 Printing oven

-There is printing oven among every colors, special designed novel, recycling wind;

-Wind volume among every colors can be adjusted by manual valve.

-The speed of wind exit is 15m/s;

-Hot air heating type.

5.10 Gearing

-Gear drive style, central drum, printing cylinder and anilox roller are all driven by gear;

-Each printing unit can start and stop during printing.

5.11 Lubrication system

-Centralized lubrication system;

-Lubricate each printing cylinder, ceramic anilox roller bearing and central drum bearing.

6.1 connection frame

-Consist of steel roller and rubber roller, connected by cross bar to ensure rigidity;

-Connection frame install ladder、traversing passage to convenience infeed and check top oven;

-Top guide roller:φ120mm.

6.2 Top oven

-Oven length 3m;

-Oven frame, up oven air cylinder unlock;

-Hot air heating;

-Nozzle type exit wind, the speed of exit 15m/s;

-consist of steel roller and rubber roller.

- Steel roller as driving roller, drived by vector frequency motor.

-Add cooling water in the steel roller to cooling the pringting material.

-Main machine enter automatic running state, rubber roller linked main machine

-Clutch pneumatic controlling of rubber roller, pressure can be adjusted.

-Vector frequency motor drive rewind shaft(YASKAWA all closed-loop vector frequency system 37KW)

-Match with DANCER ROLLER tension system to control tension;

-Match with Japan SANKEN precision potential device;

-German FESTO low friction cylinder control tension;

-Rewind taper tension control;

-Air shaft rewind, Max. dia 1200mm;

-Automatic temperature control, temperature control precision is +20C。

-Heated air is sent to various color heating oven and top oven by air fan.

The air speed of oven entrance is 15m/s.

-Eletric control box safety grade:IP40

-Rewinding and unwinding infeed、rewinding unit driving adopt closed loop vector frequency control system

- Central control panel, MMI control, printing paramter setting, system diagnosis;

-allocate still picture check system. Video head can check printing picture from left to right,

orientation at random, focus enlarge 1-20 times.

-14” color display;

-all transmission parts of machine fix s, , afety shield.

-fix explosion proof light to supply enough lighting.

-Outside of printing unit with urgent stop button;

-ma, chine safety design accord to CE standard.

-P, LC&MMI: Siemens

-Vector frequency transducer: Siemens

-Tension control system: Japan Mitsubishi

-Dancing roller control system:

Low friction cylinder FESTO

Precision throttle valve Japan , SMC

Precision potentiomter Japan SHANKEN

-Coder: Japan OMRON

-Central Roller, big gear : Italy DJM

-Temperature Control Instrument:Japan FUJI